| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : Guojin

Model Number : RWSD

Certification : ISO9001,CE

Place of Origin : China

MOQ : 1 set

Price : Negotiable

Supply Ability : 10 sets per month

Delivery Time : 20-30days

Packaging Details : Standard export Carton

Item Name : RWSD Series High Speed Atomizer Centrifugal Spray Dryer

Model Type : Centrifugal Spray Dryer

Application : Medicine Processing, Chemicals Processing, Plastics Processing, Food Processing

Power : Depand on the model

Dry Powder Recovery : >95%

Material : Stainless steel , carbon steel

Rotary speed : 8000-25000

Control : PLC touch screen

Heating source : Electricity/LPG/Natural gas/Oil/Steam

RWSD Series High Speed Atomizer Centrifugal Spray Dryer

1, High speed centrifugal atomizer spray dryer / food spray dryer / industrial spary dryer

2, Liquid or slurry drying processor

3, Easy operation and control

4, Stainless steel

Descriptions

The centrifugal spray dryer is a special equipment and is suitable for drying emulsion,suspending liquid,liquor and so on .Particularly it has unique for drying polymers and resins; dyestuff and pigment; ceramics, glass; derust agent; pesticide; carbohydrate, dairy products; detergent and surfactant; fertilizer, organic compound, inorganic compound and so on.

Principle Of Work

Application

High Speed Centrifugal Spray Dryer is widely used in foodstuff, pharmaceutical and chemical industry, such as egg powder, amino acid product, protein, blood, food flavor, food ingredients, pectin, carrageenan, spirulina, herbal extraction, pigment, cocoa, mushroom, PAC, malt dextrin, collagen, juice, yeast, Coffee, Creamer, coconut, milk, gelatin, gum and acacia etc.

Features and Outlines

Features

1. High speed of drying. After the spraying of the material liquid, the surface area of the material will be increased greatly. In the hot air flow, 95%-98% of water can be evaporated at the moment. The time of completing the drying needs only several seconds. It is especially suitable for drying the heat sensitive materials.

2. The final products own the good uniformity, mobility, and dissolving capacity. And the final products are high in purity and good in quality.

3. The production procedure is simple and the operational control easy. The liquid with the moisture contents 40-60%(for special materials, the contents may reach 90%.) can be dried into powder or particle products at a time. After the drying, there is no need for smashing and sorting, so as to reduce the operation procedures in the production and chance the product purity. The product particle diam enters, looseness and water contents can be adjusted through changing the operation codition in a certain scope, it is very convenient to carry out the control and management.

Outlines

1. Atomization: Atomizing system must ensure a uniform distribution of the fog drops, which is crucial to ensure a good qualified rate of products.

2. Contact of hot airflow and fog drops: when enough hot air enters into drying tower, the direction and angle of hot airflow have to be considered, no matter co-current flow, adverse current or mixed flow, must endure the sufficient heat exchange, it is crucial.

3. The angle design of pipelines and cone: It is very important to select the suitable angle, here we would like to share our experience and data from production of thousands of this equipment.

Technical Parameter

| Model | 5 | 25 | 50 | 100 | 150 | 200-10000 |

| Inlet temperature | 140-350 automatic control | |||||

| Outlet temperature | ~80-90 | |||||

| Max. moisture evaporation | 5 | 25 | 50 | 100 | 150 | 200-10000 |

| Centrifugal spray hear drive | Compressed air drive | Machanical drive | ||||

| Speed | 25000 | 18000 | 18000 | 18000 | 15000 | 8000-15000 |

| Spray disc diameter | 50 | 100 | 120 | 140 | 150 | 180-340 |

| Heat source | electric | electricity+steam | Electricity+steam,fuel,gas | Resolved by the user | ||

| Max. power of electric heating | 9 | 36 | 63 | 81 | 99 | |

| Outline dimension | 1.8x0.93x2.2 | 3x2.7x4.26 | 3.7x3.2x5.1 | 4.6x4.2x6 | 5.5x4.5x7 | Determined according to specific circumstances |

| Dry powder recovery | >95 | >95 | >95 | >95 | >95 | >95 |

What is the different characteristic of centrifugal spray dryer from others ?

2. The tower body is provided with an automatic vibrating device.

3. The tower body, the pipeline is equipped with the quick opening cleaning hole and the sewage hole.

4. Automatic control of constant temperature feeding tank.

5. Manual high-pressure washing tower random accessories.

6. The part in contact with the material is made of stainless steel material (or all stainless steel manufacturing.

7. The material collection adopts the two-stage cyclone dust collector, or the first stage cyclone dust collector and the wet type dust collector.

8. Automatic control of inlet air temperature and continuous device.

9. Equipped with air sweep device.

Why choose the centrifugal spray dryer to drying ?

The drying speed is fast and the surface area of the liquid is greatly increased after atomization. In the hot air flow, 95% -98% moisture can be evaporated instantly. The drying time is only a few seconds, which is especially suitable for the drying of thermos-sensitive materials.

The product has good uniformity, fluidity and solubility, high purity and good quality.

Simplified production process, easy operation and control. For 40-60% moisture content (special materials up to 90%) liquid can be dried into powder products, control and management are very convenient.

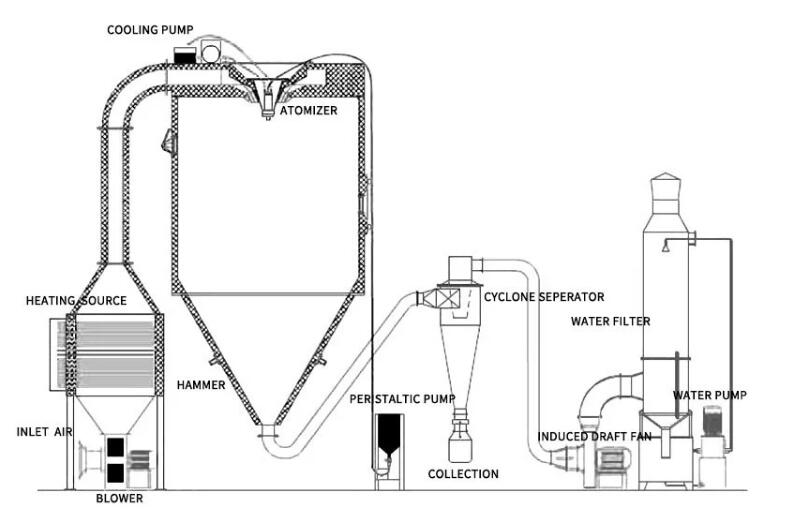

Flow Diagram

Product Show

|

|

LPG Heating 8000rpm Centrifugal Spray Dryer For Medicine Processing Images |